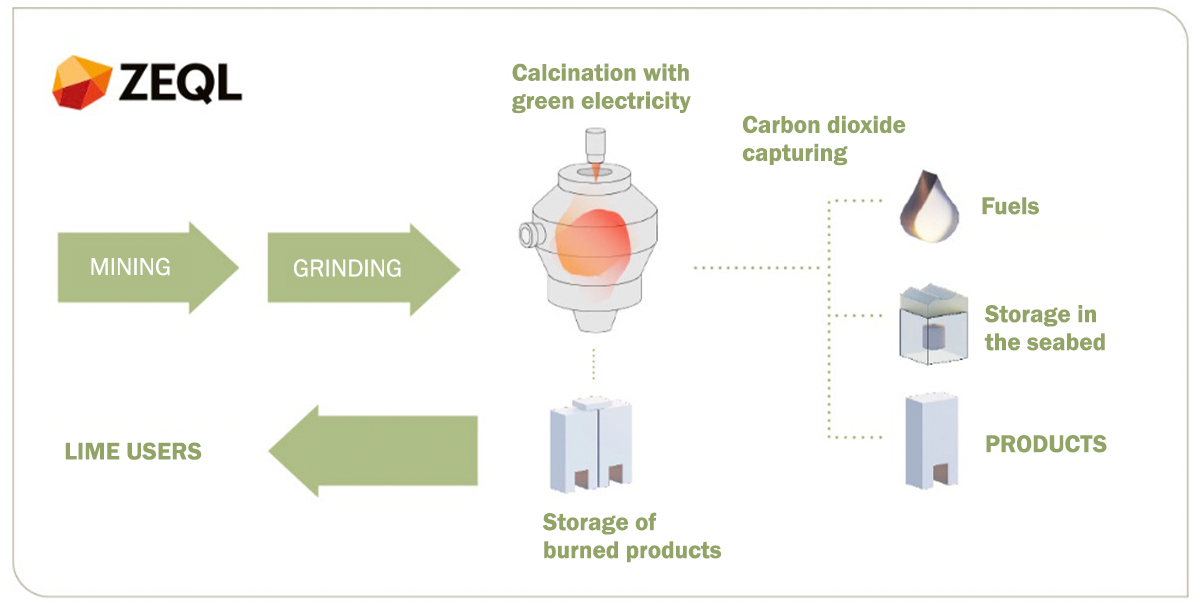

The largest, most important, but perhaps also the most challenging part of SMA Mineral’s sustainability responsibility is to significantly reduce CO2 emissions. With our and SaltX Technology’s concept ZEQL, Zero Emission Quicklime, we make it possible to achieve this goal.

The decision to reduce CO2 emissions from our calcined products by 50% is made possible through SMA Mineral’s and SaltX’s ZEQL concept. ZEQL is the first step towards achieving completely carbon-neutral production.

Plants under the ZEQL framework will operate using electricity produced without the use of fossil fuels. By switching to electricity as fuel, CO2 emissions are reduced by about 30%.

Compared to traditional kiln technology, we will be able to use a larger portion of the raw material, quarried limestone and dolomite, in the process, resulting in a significantly higher utilization rate.

To reach our long-term zero-vision, we must also capture the carbon dioxide released from the limestone during the process. By switching to electricity as fuel, we avoid the costly and energy-intensive process of separating CO2 from the emissions of a conventional lime kiln. The carbon dioxide is then available for use in processes such as the production of

electrofuels or other products. Another possibility is to store CO2 on the seabed or in products that prevent CO2 from being released into the atmosphere.

New, modern factory designs will also significantly improve the working environment, especially concerning dust.

The project is progressing rapidly, and we have made significant strides in the planning of the new factory in Mo i Rana. The new factory is planned to be operational by 2026, meaning we are on track to meet our goal.

SMA Mineral has worked intensively in 2024 to create the necessary conditions for the Mo i Rana project to be realized. An important milestone in this work has been submitting a formal electricity allocation application to Statnett. We have also presented the project to key decision-makers, including Norway’s Minister of Energy, Terje Aasland.

SMA Mineral is collaborating with several parties, such as the Mo i Rana Industrial Park, suppliers of factory components and customers who will use the product in their processes. Additionally, preparations are underway to determine how best to capture and utilize the high-concentration CO2 generated in the process.

In April 2024, we signed a letter of intent with Infinium, a U.S. company that manufactures Electro-Sustainable Aviation Fuel (e-SAF), a synthetic fuel that replaces conventional fossil-based fuel. SMA Mineral will supply high-concentration CO2 which, together with hydrogen, will serve as raw materials for eSAF. The fuel production is planned to be located near the ZEQL facility.

In February 2025, we received the exciting news that the Norwegian Enova has granted 287 million NOK in support for the construction of the pilot plant in Mo i Rana.

SaltX’s test facility in Hofors has provided valuable experience for the continued development of the technology. A larger test of ZEQL quicklime at one of SMA Mineral’s customers is planned for the spring of 2025.

SMA Mineral AB

Box 329

682 27 Filipstad

SWEDEN